Saw these in my email newsletter from Full Race

![Image]()

New 2011-2020 Manifolds by Full Race

21 - 40 of 240 Posts

Joined

·

6,025 Posts

Machined Gen1 Garrett Turbine housings. Estimated that I will loose 40hp in peak available airflow, but they will spool quicker.2017+ Garrett stage 2's? What do you do with the hot side, I thought the turbine was bigger than stock.

Joined

·

464 Posts

thanks for the discussion everyone. This is our 20th year in business, and turbo exhaust manifold design is where I cut my teeth and dedicated my engineering school education so Im irrationally passionate for this topic. Im seeing a lot of debate online regarding the number of bolts and while im eating lunch wanted to respond to the questions, clear the air and explain our decisions and vision to where we're headed - setting the stage for future turbos that dont exist yet. It's been a gigantic project for us, and I dont think any other aftermarket company is considering this. We couldnt have succeeded without our project lead Mat V and sponsorship from Dasault Systems / Solidworks (and full access to their advanced software products). Also big thank you to Jimmy Tsong at the Ford engine test lab in canada, was extremely generous with their assistance.

note: the Gen2 can't be purchased until early march (you're correct if referring to gen2)

![Image]()

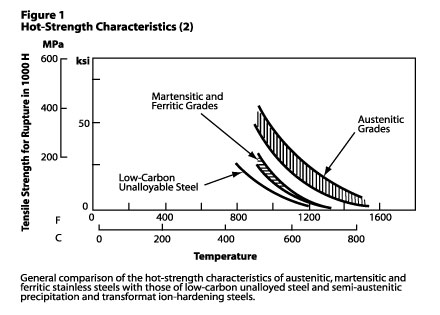

Cast iron made in sand cast tooling works fine for Diesel engines which reach 1200F EGT max. (1250 is considered the absolute extreme limit for a diesel engine).

But Gasoline engines are different - 1740F-1922F degree EGT (950C-1050C) means cast iron is NOT suitable, no matter how much silicone is added.

![Image]()

Type 347 Stainless (UNS S34700) is a columbium stabilized austenitic stainless steel with good corrosion resistance and somewhat better resistance in strong oxidizing conditions than anything else except Inconel. High end Stainless steels mfgd with lost-wax casting methods are the only material that lasts at these temperatures. The analysis and testing performed by our partners gives us the confidence to offer our customers a lifetime warranty to the original purchaser. A focus on adding superfluous bolt holes means we wouldn't be able to implement runner designs that reduce EGT and improve flow through geometry. Furthermore if there are any hardcore guys with built engines, larger turbos can not fit the Gen1 engine with OEM manifolds or any currently available aftermarket log manifold without grinding or adding spacers. Full Race Formline manifolds are the only viable way that I'm aware of that fit larger turbos in the stock location and introduce the benefits of separate runners per cylinder.

Formline Gen1 manifolds are in stock now and will start shipping all orders from our HQ here in Phoenix, AZ next week.Still can't buy them though!!!

note: the Gen2 can't be purchased until early march (you're correct if referring to gen2)

Fact is material selection followed by flange/wall thickness is the biggest factor in high temperature exhaust manifold life. More bolts won't change that reality. I fully empathize with your and others struggles failing low quality cast iron manifolds - that's why Formline manifolds were developed in thick wall high end stainless utilizing lost-wax casting methods for no inclusions/stress risersI get the apprehension given the "missing" mount point. However, these are designed completely different than any other offering. With the runner design, there just isn't any way to get that mount point in there and it keeps heat away from the flange. SS will dissipate the heat better than Carbon Steel as well. I'll be towing long distance with them, so they will be put to the test. It didn't take me very long to warp the CRP's, that's for sure.

Cast iron made in sand cast tooling works fine for Diesel engines which reach 1200F EGT max. (1250 is considered the absolute extreme limit for a diesel engine).

But Gasoline engines are different - 1740F-1922F degree EGT (950C-1050C) means cast iron is NOT suitable, no matter how much silicone is added.

Type 347 Stainless (UNS S34700) is a columbium stabilized austenitic stainless steel with good corrosion resistance and somewhat better resistance in strong oxidizing conditions than anything else except Inconel. High end Stainless steels mfgd with lost-wax casting methods are the only material that lasts at these temperatures. The analysis and testing performed by our partners gives us the confidence to offer our customers a lifetime warranty to the original purchaser. A focus on adding superfluous bolt holes means we wouldn't be able to implement runner designs that reduce EGT and improve flow through geometry. Furthermore if there are any hardcore guys with built engines, larger turbos can not fit the Gen1 engine with OEM manifolds or any currently available aftermarket log manifold without grinding or adding spacers. Full Race Formline manifolds are the only viable way that I'm aware of that fit larger turbos in the stock location and introduce the benefits of separate runners per cylinder.

When we were at PRI last month, people kept asking us why go back and develop gen1 parts? ^^^ That's exactly why. These trucks are the last steel-bodied F150s, and in all honesty they are outstanding trucks with a few improvements to the manifold / turbo / intercooler area. I personally just ticked 100k miles on our gen1 and plan to keep it until the end of time. Absolutely love the gen1 trucks for what they are - and if Full Race can improve reliability, reduce EGT and increase power, we should do that.I'm not making it a rocket but I think I want to keep it for another 100k miles... I'm thinking getting a bit more power with a bit less boost and heat will help, and a bit more fun is always welcome.

If youre going in and pulling things apart it's usually a good idea to tackle all the components at one time - manifold, turbo, gaskets, hardware and downpipe adapters in one shot. Saves effort and expense in the long run just like the intercooler/radiator/trans cooler stack,I may bite that bullet but I don't want to just replace manifolds. When I'm in there I want to waste more by upgrading the turbos too!

The brace causes the manifold/turbo to “bow” outward as it expands during extreme heat cycles. This actually makes the problem worse and breaks studs faster. The solution is the manifold must be robust enough and manufactured in thick stainless to have no issues in the expanded stateProblem is, don't the Turbos move with the block as it twists under torque? Then the brace would have to be attached to the engine and move with it?

Youre correct, the 11-12 gen1 ecoboost debuted with the “support bracket”, but it counter-intuitively actually shortened the life of the cast iron parts because it contrained the expansion as it heated up, causing even more stress on the parts. The issue is cast iron material 100% can not last forever at these temperaturesThats what Ford did for 2011 and 2012. There was a bracket from the block to an ear on the turbine housing to support the turbo. They conveniently stopped casting the turbine housing with the ear and removed the bracket in 2013. It's almost like they knew this would be an issue.

The material issue is not softening - it is warping and distorting due to overtemp and intergranular corrosion. fyi the melting point of most cast irons: ~2100F and the melting point of most stainless steels is 31% higher: ~2750FExactly. Regardless of what metal they use, its softening as it gets hotter. I dont believe that 347SS is any stronger than 316SS or carbon steel at 1500F, but I could be wrong. They may not warp but the sagging is what scares me.

I assure you, we did not design these to hold up for "a few trips down the strip". We shall seeAs I said in another thread, they may hold up for a few trips down the strip. But I’m not sure how well they will hold up to constant towing. EGTs will be much higher for a longer period of time. We shall see.

Joined

·

6,025 Posts

Thanks for chiming in on the thread Geoff, much appreciated!

Joined

·

464 Posts

Thank you for the vote of confidence. Full Race has never and will never use cast iron for any turbocharged gas engine. When I saw what people were putting on their trucks the last couple years it gave me heartburn knowing you would fail and be in the same predicament. but I never like to air dirty laundry in public and try not to talk negatively in a public forumDon't have a Gen1 with a warped exhaust manifold. But if I did it'd be difficult to not pony up for a set.

correct assumption. reliability during extreme use (like towing) was our #1 target. EGT was 2nd and fitting bigger performance turbos was 3rd.So do you think the target customer for these Full Race manifolds are tuned heavy towing (relative) Gen1 F150's? … Still, if I had to bet, I think there's considerable overlap in what would make a robust manifold and what would make a Full Race approved manifold. They don't weld that tag on anything lightly, in my opinion.

I agree, Friends dont let friends use cast iron on turbo gas engines! The decision most people should looking at are the new OEM V2 stainless manifolds or the formline stainless manifolds. The OEM manifold turbine outlet is still undersized and the runners are restrictive, the flanges are still thin, but its the best option for low cost. And if i were in your position after being burned by cast iron 3x id probably be a bit gun shy to try anything aftermarketYou can get these and test em, and ill test the new OEM ones, and we can compare notes.![:ROFLMAO: :ROFLMAO:]()

stainless steel is massively stronger at temp and in a corrosive environment like gasoline engine exhaust there's no comparison.The CRP's are burly, and better steel, but they still pull away from the head in that same spot without popping the studs, at least not in my case. I allegedly "warped" 3 CRP's and my studs were all there. Stainless steel is not actually stronger.

Respectfully, I believe CRP is not a superior material to OEM... hence your experience. Sand-cast iron (CRP) and the other slightly better option of sand-cast Hi-Sil-Mol (BD Diesel). Neither material is suitable for a turbocharged gasoline truck application. Every modern performance gasoline engine has a stainless turbine housing and manifold for this reason. Garrett stopped using cast iron housings on all their performance turbos in 2008 for this exact warping/cracking concern. Garrett switched to ni-resist for cheaper turbos and 347 stainless for the high end g series

I apologize if you did not get a prompt response while we were away at PRI that week. We brought the entire team out to Indianapolis and the office only had 1 guy answering phones. that was a mistake. The whole team regrets that customers didnt get the attention that they deserve that week. It won’t happen again, some of our guys are staying behind next year. thank you for your patience!.I’ll probably end up getting the full race manifolds once they come out, although they haven’t shipped my turbo adapters yet and it’s been 10 days since I ordered them lol and they haven’t responded to my email inquiry I sent about it a couple days ago, hopefully they are just busy or something… They just emailed me back and said that they ran out of hardware for them so might be a little bit to get it back in stock.

my pleasure. happy to answer any other questions you haveThanks for chiming in on the thread Geoff, much appreciated!

At my age it's STILL amazing to discover that I don't know what I don't know.

So glad I was born late enough to at least get to witness the information age, if you know what I mean. Forums are invaluable regarding.

So glad I was born late enough to at least get to witness the information age, if you know what I mean. Forums are invaluable regarding.

Joined

·

12,923 Posts

Hey @full-race geoff - outstanding contribution to our forum and great information to help us understand what's what.

Thank you!

Please PM me a mailing address and count of the number of guys on the team in the office. I'll send each one of the team one of our F150Ecoboost.net decals - except that guy you left behind to answer the phones. He will get one regular and one of the retired 10th Anniversary decals! He earned it!

Thank you!

Please PM me a mailing address and count of the number of guys on the team in the office. I'll send each one of the team one of our F150Ecoboost.net decals - except that guy you left behind to answer the phones. He will get one regular and one of the retired 10th Anniversary decals! He earned it!

Joined

·

12,385 Posts

My understand from doing work in fire protection of stainless and carbon steel assets in oil refineries and chemical plants, that stainless steels yield strength was no better than carbon steels(lower at low temperatures), and in fact the structural failure points for stainless steel assets are generally at a lower temperature during a fire. Our fire testing temperatures are 2000-2350F.stainless steel is massively stronger at temp and in a corrosive environment like gasoline engine exhaust there's no comparison.

Respectfully, I believe CRP is not a superior material to OEM... hence your experience. Sand-cast iron (CRP) and the other slightly better option of sand-cast Hi-Sil-Mol (BD Diesel). Neither material is suitable for a turbocharged gasoline truck application. Every modern performance gasoline engine has a stainless turbine housing and manifold for this reason. Garrett stopped using cast iron housings on all their performance turbos in 2008 for this exact warping/cracking concern. Garrett switched to ni-resist for cheaper turbos and 347 stainless for the high end g series

Warping and cracking, for sure I can see it being better.

But maybe im missing something.

And to be clear, I am not arguing that the manifolds should be carbon steel. I am fully on board with the stainless options. I am running the stainless OEM manifolds on my truck right now instead of CRP's or BD's. My concern stems from the 9" gap between the two rear most upper studs. My CRP's pulled away from the rear most port without breaking studs

Joined

·

464 Posts

love it - never ever stop learning. and for the record, gen2 is soo much easier than gen1At my age it's STILL amazing to discover that I don't know what I don't know.So glad I was born late enough to at least get to witness the information age, if you know what I mean. Forums are invaluable regarding.

thank you, will do the guys will be pumpedPM me a mailing address and count of the number of guys on the team in the office. I'll send each one of the team one of our F150Ecoboost.net decals - except that guy you left behind to answer the phones. He will get one regular and one of the retired 10th Anniversary decals! He earned it!

Im not here to argue with you but there's no 9" gap.Warping and cracking, for sure I can see it being better. But maybe im missing something. And to be clear, I am not arguing that the manifolds should be carbon steel. I am fully on board with the stainless options. I am running the stainless OEM manifolds on my truck right now instead of CRP's or BD's. My concern stems from the 9" gap between the two rear most upper studs. My CRP's pulled away from the rear most port without breaking studs

not surprised that low grade cast iron was pulling away. im glad you are happy with the oem V2 stainless manifolds

Joined

·

833 Posts

Stoked that the manifolds are finally finished and available. I’ll be ordering some as soon as I call FR and confirm options in the morning.

What peaks my interest most is this little nugget!…

Any more detail to be offered? Any future turbos currently in development?

What peaks my interest most is this little nugget!…

Any more detail to be offered? Any future turbos currently in development?

explain our decisions and vision to where we're headed - setting the stage for future turbos that dont exist yet.

Joined

·

6,025 Posts

Some pics of the Stage 2’s bolted to the form line manifolds.

![Image]()

![Image]()

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Joined

·

12,385 Posts

Ok, sorry, however long this gap is. I left me ruler and manifold in the garage. That is where every single one of my 4 manifolds leaked. Top of the rear most portlove it - never ever stop learning. and for the record, gen2 is soo much easier than gen1

thank you, will do the guys will be pumpedI walked out to the parking lot this morning and realized almost all our staff drives F150s from 2006 to 2022 in the lot

Im not here to argue with you but there's no 9" gap.

not surprised that low grade cast iron was pulling away. im glad you are happy with the oem V2 stainless manifolds

2015 Lariat Screw 5.5' | 3.5 Eco | 4x4 3.55 Max Tow Twin Turbo Dadmobile

Joined

·

2,378 Posts

I’m not any expert on metallurgy but I appreciate all the food for thought here!

Disclaimer: software engineer here, not mechanical.

One thing I haven’t seen mentioned is metal “memory”. E.g regardless of any expansion or Strength changes by temperature, what seems just as or possibly more important is if the shape will go back to normal.

Maybe this is where the material and design gains another advantage.

In theory if everything from the head to the studs to the turbine housing to the manifolds expands and returns in a somewhat consistent fashion, maybe it’s less important what the specific strengths are at specific temperatures? Or how many times the metal will return?

If I recall cast iron has little to no “tensile memory” if I’m remembering the term correctly.

Disclaimer: software engineer here, not mechanical.

One thing I haven’t seen mentioned is metal “memory”. E.g regardless of any expansion or Strength changes by temperature, what seems just as or possibly more important is if the shape will go back to normal.

Maybe this is where the material and design gains another advantage.

In theory if everything from the head to the studs to the turbine housing to the manifolds expands and returns in a somewhat consistent fashion, maybe it’s less important what the specific strengths are at specific temperatures? Or how many times the metal will return?

If I recall cast iron has little to no “tensile memory” if I’m remembering the term correctly.

Joined

·

1,841 Posts

@full-race geoff - The pics on your web page shows all the mounting hardware and gaskets. Does this come as a kit with new manifolds?

Also, what is the difference in choosing WITH or WITHOUT the GARRETT POWERMAX TURBOS?

I ask because I may just buy these now and wait until later to get turbos and do everythign at once but spread the cost out strating now.

Thanks for all you input!!

Also, what is the difference in choosing WITH or WITHOUT the GARRETT POWERMAX TURBOS?

I ask because I may just buy these now and wait until later to get turbos and do everythign at once but spread the cost out strating now.

Thanks for all you input!!

Only history, which doesn't exist yet, is going to confirm whether what all the "testing" suggests. And I don't fault any scepticism since the Gen1 warped manifold fix has already been claimed in the past only to prove out to not be true.

But this time I personally believe does warrant fresh optimism. It's far from just another thick(er) lump of cast iron with an altered bolt pattern.

What sticks out in my mind is the term "huge project".

Thicker with altered bolt pattern wouldn't deserve such a description with any meaningful sincerity. It's obvious that so much more went into this than what our eyes could possibly see in a computer screen image.

But this time I personally believe does warrant fresh optimism. It's far from just another thick(er) lump of cast iron with an altered bolt pattern.

What sticks out in my mind is the term "huge project".

Thicker with altered bolt pattern wouldn't deserve such a description with any meaningful sincerity. It's obvious that so much more went into this than what our eyes could possibly see in a computer screen image.

Joined

·

833 Posts

From what I was told the manifolds ARE a kit which include gaskets, studs, and nuts; not 100% which gaskets and hardware are included though.@full-race geoff - The pics on your web page shows all the mounting hardware and gaskets. Does this come as a kit with new manifolds?

Also, what is the difference in choosing WITH or WITHOUT the GARRETT POWERMAX TURBOS?

I ask because I may just buy these now and wait until later to get turbos and do everythign at once but spread the cost out strating now.

Thanks for all you input!!

I was told the selection for Garrett powermax turbos includes an additional wastegate arm adapter thing.

On their website it currently does not allow you to add to cart with the powermax selection. You can add to the cart if you select “no powermax turbos”

Joined

·

833 Posts

FYI- Also currently unable to complete checkout due to “no shipping quote available”

Joined

·

833 Posts

Those look like they’re bolted to gen1 manifolds too. Any more details?Some pics of the Stage 2’s bolted to the form line manifolds.

![Image]()

![Image]()

Sent from my iPhone using Tapatalk

Joined

·

6,025 Posts

This is the set that is apparently heading out my way in the very near future. Yes, these are the Gen1 Manifolds (for obvious reasons). The Turbo's are the Garrett Stage 2's with some provisions to work with a Gen1 motor and Gen 1 manifolds.Those look like they’re bolted to gen1 manifolds too. Any more details?

- Gen 1 Garrett Upgraded Turbo Turbine housings that have been machined to accommodate the larger Stage 2 turbines

- Mid-boost Vacuum WG actuators with FR Adapter mounts

- Ship with the "OEM" sized inlet installed and the 2.5" inlets will come with to be swapped at my discretion.

These are smaller A/R turbine housings than the original Stage2's, I am anticipating them to spool really quick, however a draw back of up to 4#/min in peak airflow.

I'll probably start a separate thread on my set up once I have them in hand. They won't be installed for a little while though, unless I just put them in without the injectors. I'm not crazy about the wiring solution from XDI and may have to figure something different out.

The idea is to hammer out a tuning plan with @Boostking and document the journey and subsequent testing. I think I may be the first one to get my hands on this set up.

Joined

·

6,025 Posts

Sweet! Mine will be shipping next week.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Joined

·

464 Posts

Hi Scott, that's correct - this is a 'kit' with the manifolds and includes 100% OEM Ford gasket and OEM studs (in Ford packaging)@full-race geoff - The pics on your web page shows all the mounting hardware and gaskets. Does this come as a kit with new manifolds?

the difference is WITH GARRETT POWERMAX includes a low-profile Garrett powermax wastegate arm/canister (low boost). This is a direct swap for the weird Garrett powermax canister which is unusually large diameter (nobody knows why it's so fat).what is the difference in choosing WITH or WITHOUT the GARRETT POWERMAX TURBOS?

totally understood. it would probably make the most sense to order the manifolds with powermax turbos to get the actuators with the manifolds to start with. then you can get the turbos and the downpipe adapters together later onI may just buy these now and wait until later to get turbos and do everything at once but spread the cost out starting now.

100% correct. thanks for posting up. I think they are adding the powermax low profile actuator to the site tomorrow or weds. will confim in the morningFrom what I was told the manifolds ARE a kit which include gaskets, studs, and nuts; not 100% which gaskets and hardware are included though. I was told the selection for Garrett powermax turbos includes an additional wastegate arm adapter thing. On their website it currently does not allow you to add to cart with the powermax selection. You can add to the cart if you select “no powermax turbos”

Thanks you I will let them knowFYI- Also currently unable to complete checkout due to “no shipping quote available”

its not a production turbo ready for purchase yet. Expecting Q2/Q3 for these, they're rototype turbos designed to test garrett's stage2 powermax viability on the gen1. its not a production part yet, and there are some questions that testing will answer, but this is new territory and not for normal consumption. worth noting if you werent already aware, the Gen1 is more difficult install than the Gen2 due to the hardline plumbing differences.Those look like they’re bolted to gen1 manifolds too. Any more details?

The Turbo's are the Garrett Stage 2's with some provisions to work with a Gen1 motor and Gen 1 manifolds.

- Gen 1 Garrett Upgraded Turbo Turbine housings that have been machined to accommodate the larger Stage 2 turbines

- Custom Mid-boost Vacuum WG actuators with FR Adapter mounts

- Ship with the "OEM" sized inlet installed and the 2.5" inlets will come with to be swapped at my discretion

please try them on your initial injectors. no other changes. the oem injectors work pretty well with a big pump behind themThey won't be installed for a little while though, unless I just put them in without the injectors. I'm not crazy about the wiring solution from XDI and may have to figure something different out. The idea is to hammer out a tuning plan with @Boostking and document the journey and subsequent testing. I think I may be the first one to get my hands on this set up.

that's a 6" span - perfectly acceptable for stainless steel. Look at the new bronco 2.7 and 3.0 for example, they are 5.7"Ok, sorry, however long this gap is. I left me ruler and manifold in the garage. That is where every single one of my 4 manifolds leaked. Top of the rear most port

21 - 40 of 240 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 674K

- members

- 53K

- Since

- 2012

F150Ecoboost.net is the best Ford F150 Ecoboost Forum with discussions on 2011+ F150 Ecoboost Trucks. Discuss performance mods, towing questions, wheels, tires, lift kits, and much more!

Top Contributors this Month

View All

FanaticalKilla

151 Replies

snakebitten

100 Replies

butthead

65 Replies